|

| (Source: VGA Museum) |

3Dlabs was founded in April 1994 and announced the Glint 3D rasterizing engine for high-end 3D CAD applications in November of that year.

Glint was the first fully integrated, OpenGL-compatible workstation graphics chip. Other companies like ATI, Dynamic Pictures and Nvidia would also develop OpenGL workstation-class chips, while more established larger companies, such as Evans & Sutherland, HP, IBM, Intergraph, SGI, and SUN often referred to as the “big iron” companies, built complex large graphics boards with multiple proprietary processors. All of those “big iron” companies would succumb to the economic advantages of the single-chip designs and using the mass-market high-volume production of the core design behind them. The “big iron” suppliers would either adopt the use of the single-chip parts, or retreat from the market as DEC, E&S, IBM, Intergraph, Lockheed, SGI, and SUN did. By 2000, those big companies had begun exiting the graphics market and began the long painful process of shrinking; some, like DEC, didn’t make it.

The first Glint chips offered the equivalent of a high-end Silicon Graphics Indigo graphics in a single chip—for less than the cost of the VRAM framebuffer memory. The Glint chips provided 24-bit 2D and 3D acceleration, on-chip PCI interface, and LUT-DAC control, making a complete graphics subsystem possible with minimal chip count.

The smaller more agile companies kept pushing the technology and in 1997 3Dlabs developed its Glint Gamma processor, the first programmable transform and lighting (T&L) engine for its Glint workstation graphics chips and even coining the terms GPU—geometry processor unit before Nvidia announced its graphics processor unit (GPU). 3Dlabs’ GPU was a separate chip named Delta. Prior to the introduction of the Delta chip, T&L was being done by the floating-point processor in the CPU and in some cases with DSPs.

Whereas 3Dlabs GMX was a co-processor to the Glint SX and MX rasterizer, Nvidia developed an integrated T&L engine for their consumer graphics chips which they were branding GeForce. ATI quickly followed with their Radeon graphics chip. By the end of 1999, the number of graphics chip suppliers had dropped to 12, and the consolidation was not over yet—even though the market was rapidly expanding, the commodity suppliers were dying—innovate or die.

The Glint 300 SX was manufactured in 1994 using IBM’s 3.3V, 0.5-micron process, and the chip operated at 2.5 billion operations/second and sold for $150 in volume.

Right on the heels of the Glint SX, 3Dlabs introduced the Glint TX. Both the 300SX and 300TX were extremely advanced in design. They used one million transistors and ran at the equivalent of 2.5 Giga Operations per second. In comparison, a typical VGA chip of the time used 50K transistors.

Glint was designed to process primitives (e.g., triangle) that were generated by an application and passed to Glint via the OpenGL API. Glint was referred to as a rendering pipeline processor.

Triangles were passed through the pipeline and messages were generated as to what should happen in each stage. The primitive was Gouraud shaded Z buffered triangle(s), with dithering.

|

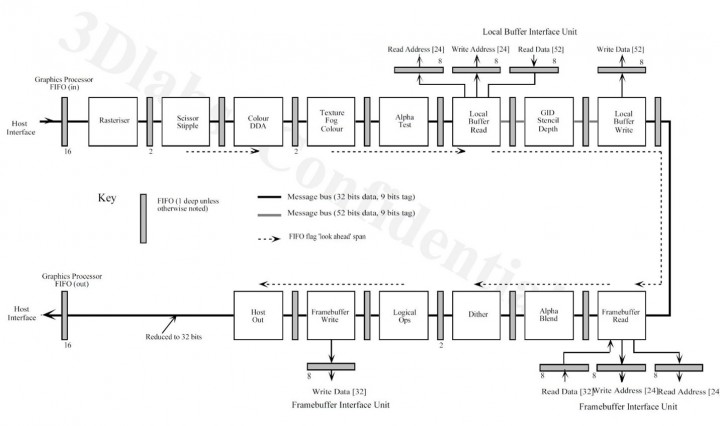

| Figure 1: Glint block diagram. (Source: Neil Trevett) |

The application generated the triangle vertex information and made the necessary OpenGL calls to draw it.

The OpenGL server/library would take the vertex information, transform, clip, and light it. It would then calculate the initial values and derivatives to interpolate position and color depth. All those values were in fixed point integer and had unique message tags. Some of the values (the depth derivatives) had more than 32 bits to cope with (for dynamic range and resolution) and were sent in two halves. Finally, once the derivative’s start and end values had been sent to Glint, the 'render triangle' message was sent.

In computer graphics, a digital differential analyzer (DDA) is hardware or software used for the interpolation of variables over an interval between start and endpoint. DDAs are used for the rasterization of lines, triangles, and polygons.

In Glint, the derivative, start, and end parameter messages were received and flowed down the message stream to the appropriate function blocks. The depth parameters and derivatives were sent to the Depth Unit; the RGB parameters and derivative to the Color DDA Unit; the edge values and derivatives were sent to the Rasterizer Unit.

|

| Figure 2: Glint 300SX core architecture. (Source: Neil Trevett) |

The 'render triangle' message was received by the rasterizer unit and all subsequent messages (from the host) were blocked until the triangle had been rasterized (but not necessarily written to the frame store). A 'prepare to render' message would be passed on so any other blocks could prepare themselves.

3Dlabs continued to expand the product line and in 1997 introduced a smaller, faster model, the Glint MX. The MX was a high-performance graphics processor that combined workstation-class 3D graphics acceleration and state of the art 2D performance in a single chip. All the 3D rendering operations were accelerated by the MX, including Gouraud shading, texture mapping, depth buffering, antialiasing, and alpha blending. Implemented around a scalable memory architecture, the MX reduced the cost and complexity of 3D graphics within a windowing environment and MX was pin-compatible with the 300SX and 500TX processors.

|

| Figure 3: The Glint MX processor. (Source: Neil Trevett) |

The Glint rasterizers and OpenGL accelerators were delivering what the company promised but were being held back by the processing speed and I/O of the CPU’s floating-point capability. 3Dlabs knew that would be a problem and had hoped Moore’s Law would solve the issue, but it didn’t and so the company developed its own FFP but as a dedicated geometry processor rather than an inherently slower general-purpose FFP—they called it the Delta processor, and it was designed to be a co-processor to the Glint.

|

| Figure 4: 3Dlabs’ roadmap in the mid-90s. (Source: 3Dlabs) |

While initially targeting traditional 3D applications including CAD, 3Dlabs told JPA they envisioned the long-term market including games, multimedia, VR, and interactive television. And although the company did get into bed (somewhat coyly, it turned out later) with Creative Labs, 3Dlabs in the consumer marketplace was still some ways off with its Permedia.

The market was still wide open. Windows NT 4.0 was a year away, and the applications base that 3Dlabs needed was still two years away. So between 1994 and 1996, anything to do with professional 3D graphics was considered fair game. Intel bought into Lockheed Martin’s 3D intellectual property, knowing that even back in 1995, the company was weighing its options in a Windows dominated, post-cold war world.

What 3Dlabs did that no other manufacturer had managed to imitate or come close to doing was to completely focus on their PC OEM customers. People in the industry saw the Intel roadmap, the Microsoft roadmap, and companies like Compaq had already figured out that UNIX was their next target. This was a time when the PC industry stood on the brink of world domination and was looking for foes to vanquish. This was also a time when Apple was seeming to lose ground, and a recession-hit industrial society was looking to save money and still make progress.

The other thing that 3Dlabs did well was to sell professional graphics to an audience that knew nothing of it. Much of the interest in PCs in the middle years of the nineties was surrounding multimedia. 3Dlabs evangelized the sexiest component and one that was out of the reach of most users and developers, realtime 3D. It helped to have SGI preening around in full glory at the same time, splashing Hollywood special effects at the traditionally staid computer shows. It also helped to have a host of APIs promising to enable the next generation in mass-market 3D applications. Remember Reality Labs and Intel’s 3DR?

The initial problem that 3Dlabs had in evangelizing the market was one that faces companies today: the PC versus workstation debate. Ultimately, 3Dlabs and other like-minded souls saw that the workstation market was where the applications were for professional graphics and that until there was a compelling reason to do so, they wouldn’t move to the PC. It’s worth bearing in mind that in the pre-Windows 95 and NT 4.0 eras there was still some question as to whether the PC wouldn’t just end up being a 3D game machine and there was some level of confusion over how much software rendering was going to be done by APIs such as RenderWare and Reality Lab. The PC graphics market was caught a little flat-footed by the professional graphics market.

3Dlabs wasn’t. Neither were the companies who bought into their technology: Elsa, SPEA, Omnicom, and, eventually, AccelGraphics. These companies, big or small, still carried with them the experience and expertise of AutoCAD graphics sales and were bolstered by workstation savvy developers. Siggraph 94 was the beginning of momentum behind OpenGL, and Microsoft was showing its support for the API by including it in the beta CD for Daytona, which would eventually go on to become the NT platform of version 3.0.

Permedia

In 1995, the company introduced its Permedia graphics processor. With Permedia, 3Dlabs answered all complaints its competition had against the Glint (too expensive, too high-end, no VGA, no PCI, uses only VRAM, requires Z-buffer, etc.). Its technology partnership with IBM has shown up in several ways: 3.3V, 0.35µ fabrication, a special version of the 562-process, and VGC/PCI capability. This part, with its 3D Blaster game compatibility and the 3Dlabs long list of OEMs, ushered in a new wave of game boards for the PC. The chip sold for $50.

|

| Figure 5: 3Dlabs’ Permedia consumer-level 3D controller (Source: PC Graphics Report) |

3Dlabs continued to pick up the established workstation companies and several others. And in 1996 TI would renew its interest in graphics by licensing 3Dlabs’ design for the Permedia.

The advantage competitors like ATI and Nvidia had was they could adapt the chips they were developing for the mass consumer market to the smaller volume professional graphics market. To try to counteract this situation, 3Dlabs announced a lower-cost version of its high-end chip in the Permedia. Creative Labs was one of the first to adopt the new chip. But the chip, as good as it was, could never reach the price points and design cycles that ATI and Nvidia were hitting and 3Dlabs found itself losing market share and sales.

The company had gone public in April 1994 and armed with a tangible financial vehicle, its stock, went looking for acquisitions to broaden its capabilities.

In July 1996, 3Dlabs acquired Dynamic Pictures, a competitor. Dynamic Pictures was spun out of DEC in 1993. Digital developed 3D chips at its Palo Alto design center in the early nineties and then, as the company began retrenching and selling off assets, it closed the facility. Dynamic Pictures was then founded in 1993. The founders had worked for eight years at DEC where they developed 3D graphics workstation products including the ZLX-M/L graphics line. The original technology was developed as part of the PixelVision project within DEC.

The first T&L processor

In November 1997, at the Comdex conference, 3Dlabs announced two new high-performance chipset families in its Glint family: the Glint DMX and the Glint GMX (code-named Gamma). These chipsets provided geometry and rasterization performance and accelerated the same 3Dlabs 2D/3D driver set, and the company claimed at the time that they would accelerate graphics tasks such as transforms, lighting, clipping, and texture-mapping rates to 66 million pixels per second.

Both Glint DMX and GMX families supported high-resolution displays up to 2K × 2K at true color, large texture memories up to 96 Mbytes, and deep 32-bit color & Z-buffers. Both chipsets also accelerated OpenGL 1.1 rendering operations including Gouraud shading, advanced texture-mapping, per-pixel mipmapping, tri-linear texture filtering, anti-aliasing, multi-plane stenciling, and alpha blending with destination alpha support. By February 1998, the company was providing sample quantities of the GMX to selected OEM customers.

3Dlabs developed what was the first, multi-chip implementation of a geometry processing unit—a GPU. However, they called the chipset a Video Processing Unit—VPU. Later, when Nvidia introduced the first fully-integrated graphics processor unit—GPU, 3Dlabs reconsidered their naming.

In 1999, workstations were being built that used a new high-speed serial memory called Rambus. And in 1999, 3Dlabs introduced the Glint Rx that use Rambus for its memory—the first graphics chip to do so.

Then in April 2000, 3Dlabs announced it would acquire the Intense3D division of Intergraph. Intergraph’s Intense3D division (Huntsville, AL) 3D-T Pro 1000 was a competitive board to 3Dlabs boards. As part of the deal, 3Dlabs agreed it would continue to supply Intergraph with graphics products for its workstations and media processing products.

Paradise lost

The origin of 3Dlabs starts in 1983 when Osman Kent and Yavuz Ahiska started benchMark Technologies in London. They sold benchMark to DuPont in 1988 for $12 million, and it became DuPont Pixel.

|

The managers of DuPont Pixel made, and DuPont accepted a buyout offer, and in 1994 3Dlabs was established. The company immediately released details on the Glint family of 3D graphics processors—the 300SX and 300TX—in April 1994.

The company developed a series of high-performance graphics processors and entered the consumer segment with its popular Permedia processor in 1995.

It then acquired two competitors strengthening its position in the workstation segment. But larger companies like ATI and Nvidia overwhelmed 3Dlabs with faster product introductions and lower cost parts due to the economy of scale of supplying the emerging PC gaming and commercial segments.

When the Internet bubble popped 3Dlabs was losing money and market share and could no longer compete.

In June 2002, Creative Labs, 3Dlabs long-time partner, bought the company. Then at the beginning of 2005, Creative Labs shut down the workstation business of 3Dlabs and announced it would stop developing professional 3D graphic chips and focus on embedded and mobile media processors. The new media processor products, developed in the original 3Dlabs UK R&D center by most of the workstation graphics chip designers, was designated ZiiLabs.

In December 2006, Creative Labs spun off 3Dlabs and created ZiiLabs, with a lot of the same R&D people in the UK from the Benchmark Technologies days.

In July 2007, the consumer version “Gigi” was developed with Creative labs and gave 3Dlabs the distinction of being the first to ship a 3D games chip—“Gigi.”

The Elsa add-in board in the introductory picture is equipped with a 3Dlabs setup and rendering engines and 40MB of on-board RAM. The ELSA GLoria-XL ($1,650) was nonetheless a lackluster performer on most of the benchmarks in 1998. The GLoria-XL was built around 3Dlabs' Delta geometry processor and Glint MX rendering chip, with a 16MB VRAM frame buffer and up to 40MB of EDO DRAM texture memory, which produces 24-bit double-buffered resolutions up to 1920 × 1080.

3Dlabs was a pioneer, the first to implement OpenGL in silicon, the first to build a commercial geometry and lighting engine, and the first to use Rambus, and to drive massive texture maps. The company’s IP portfolio still runs through the industry and is the source of comfort for a few companies because of the foundational protections it offers.